Global Fashion Summit 2024: Technology & Business Models We're Watching

Takeways and learnings from the summit in Copenhagen

Its been a few days since the Global Fashion Agenda culminated in the lovely, Copenhegan, the Danish capital and I’ve finally had the time to gather my thoughts.

The city of Copenhagen itself boasts of a very strong repertoire in its ambitious sustainable goals with its thriving organic food scene, focus on cycling infrastructure (which beats Paris, which is already quite a significant achievement, might I add), heavy investments on renewable energy resources, and home to the majestic CopenHill, a ski slope built on top of a waste-to-energy plant (in fact, they are aiming to become completely waste-free by 2025)!

The Copenhill, Copenhill, also known as Amager Bakke, is a unique building in Copenhagen, Denmark, that combines two seemThe Copenhill, a Waste-to-Energy Plant and a Recreational Facility

The ski-slope at the CopenHill

A round of applause. And, back to the Summit.

The 15th Annual Global Fashion Summit in Copenhagen's iconic Concert Hall challenged attendees to move beyond presentations and into action. While some sessions felt like a retread of old ground, others offered fresh perspectives and a call to arms. On that note, I'm excited to share some inspiring discoveries from the Summit!

With a lens on Business & Technology, here are the things we are watching from the Global Fashion Summit 2024.

Part I: The Business Models

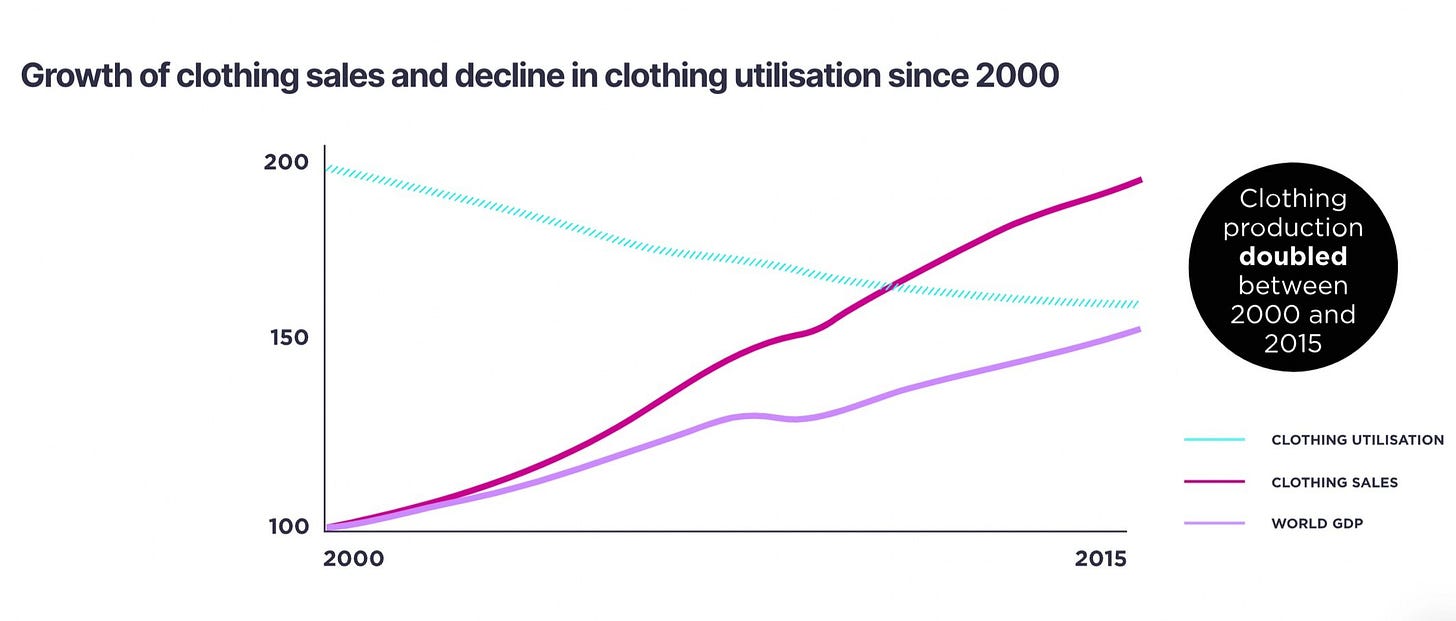

Circular Models: decoupling revenue from production

Ellen McArthur Foundation, announced the The Fashion ReModel, a demonstration project involving leading brands from across high-end, activewear, retailers, mid-range and high-street. It aims to identify solutions and unlock barriers in order to scale circular business models and begin to decouple revenue from production.

Circular business models offer both revenue and cost benefits. They provide multiple revenue streams by enabling businesses to offer new services, such as restoration, customisation and tailoring. Revenue benefits include increased loyalty, access to customer and product use data and increased customer base. At the same time, costs can be reduced due to savings from better resource productivity and risk reduction (e.g. improved inventory management).

Resale, rental, repair and remaking are already worth more than USD 73 billion – and growing. Since 2019, and despite the global Covid-19 pandemic, seven resale and rental platforms – Depop, Rent the Runway, The Real Real, Vinted, Poshmark, Vestiaire Collective, and ThredUP – have reached billion-dollar valuations. These business models have the potential to grow from 3.5% of the global fashion market today to 23% by 2030, becoming a USD 700 billion opportunity, while providing significant environmental savings from increased use and reduced production.

(Quoted from Ellen MacArthur Foundation, Circular business models: redefining growth for a thriving fashion industry (2021).)

Collective Financing: a strong incentive for suppliers to decarbonise

The Fashion Pact in partnership with Apparel Impact Institute, Guidehouse, and DBS Bank, announced brands commitment to the Future Supplier Initiative – a collective financing model for brands to support suppliers in accessing affordable loans to decarbonise their factories. FSI develops and finances projects that allow mills, manufacturers and brands to achieve near-term Science Based Targets with an intent to reduce Scope 3 emissions. More details about this partnership out on June 13th on their website.

The case for wages: a legally binding collective bargain for worker wages in Cambodia

Appallingly low wages in garment manufacturing fuel the horrors of modern slavery. Collective Bargaining Agreements (CBAs) offer a powerful new weapon in Cambodia. Unlike brands' past reliance on non-binding CSR initiatives, CBAs empower trade unions to fight for fair wages and working conditions, finally putting an end to empty promises.

ACT (Action, Collaboration, Transformation) is an agreement between IndustriALL Global Union and international brands and retailers in the garment and footwear industry to support sustainable wage growth through collective bargaining in production countries. Under this CBA, the brands vow to:

Secure production volumes with suppliers for long-term planning

Offer sourcing incentives that encourage ethical practices

Ring-fence labor costs to ensure fair wages are prioritized

Fund worker skill development programs for a thriving workforce

Part II: What’s up in Tech?

Measuring fashion’s carbon footprint

The upcoming enforcement of regulations like CSRD and the growing importance of SBTi initiatives to meet Paris Agreement goals are driving a surge in focus on sustainability reporting within the fashion industry.

With brands like Vuori, Patagonia, and amidst several others as their clients, Worldly is a platform that helps brands and retailers gather a better view of their value chain. It helps them track factory impacts, fulfill requirements for sustainability reporting, and understand the impact of their products.

Leveraging AI to end over-supply

Having worked with fashion brands and having faced some serious challenges with surplus inventories, as well as as deep costs that they incur, I think this tech is game-changing.

As Ahmed Zaidi from Hyran pointed out, the industry needs to move beyond forecast-driven models towards a more agile approach. Predicting what will sell 18 months in advance is a near-impossible feat, but by redesigning processes for shorter production lead times, we can leverage technology to react to real-time demand. This shift offers a powerful solution to the oversupply crisis.

At the Innovation Forum, speaking with Kasper from Hakio I learnt that it aims to solve a similar problem. Based out of Denmark, Hakio aims to revolutionise demand-forecasting in fashion & apparel industry by switching from Excel sheets to AI-powered algorithms. Excited to see where they go from here and the impact these technologies will likely have in the coming years.

Transparency in our waste flows

At the Innovation Forum, I indulged in all my waste related queries with Reverse Resources’s Raffaella Carluccio. The Reverse Resources platform connects four key players in the textile recycling loop:

Waste Suppliers: These are generators with detailed waste info (e.g., garment factories).

Waste Handlers: They process waste before turning it into new products (e.g., sorting facilities).

Recyclers: They use pre-processed waste to create new textile materials.

Brands: They track their waste streams throughout the supply chain.

They are already in 34 countries across the world, working with 169 recyclers and 140 waste handlers.

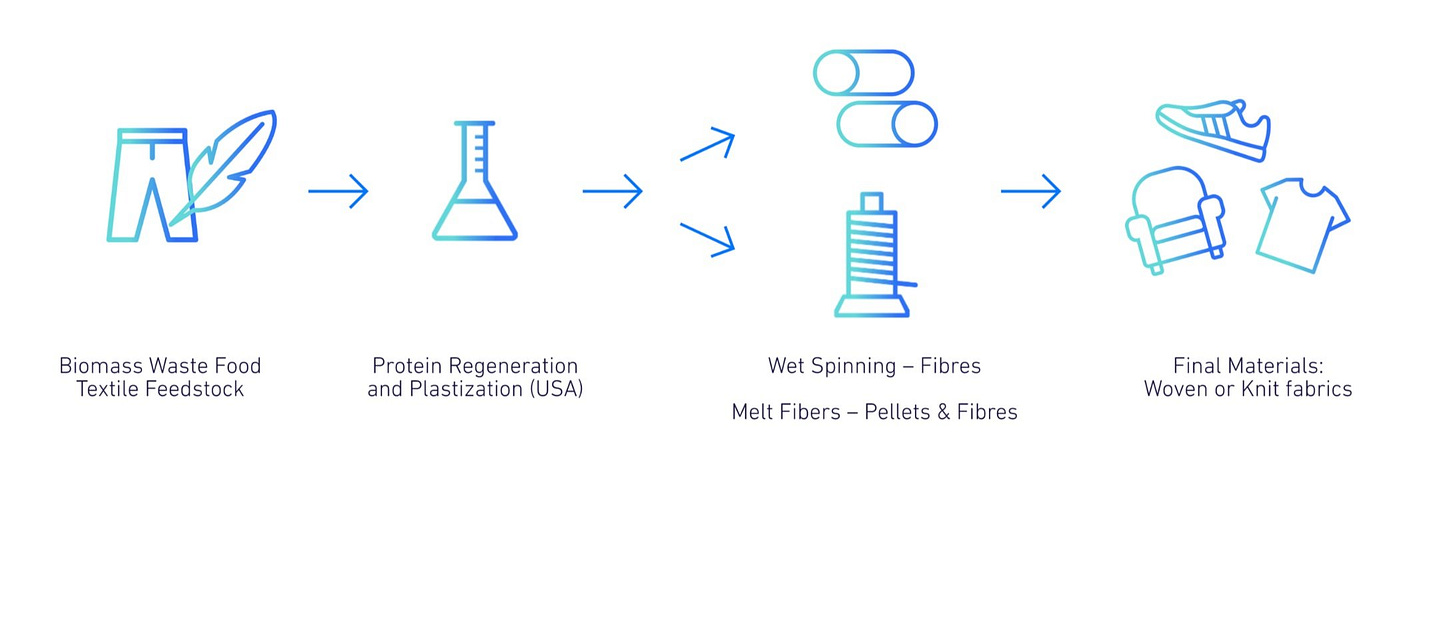

Regenerative materials

Super excited about this year’s winner of the Trailblazer Programme- Bloom Labs. Bloom Labs is accelerating the transition towards a circular economy by tapping into the billions of tons of fibrous protein waste produced annually to create bioplastics and textile fibres at scale. Through a closed-loop process and 100% bio-based ingredients, they combine the best of natural fibres, such as handfeel, breathability and softness, with the efficiency of industrial fibre processing, reducing the use of resource-intensive natural fibres and synthetics.

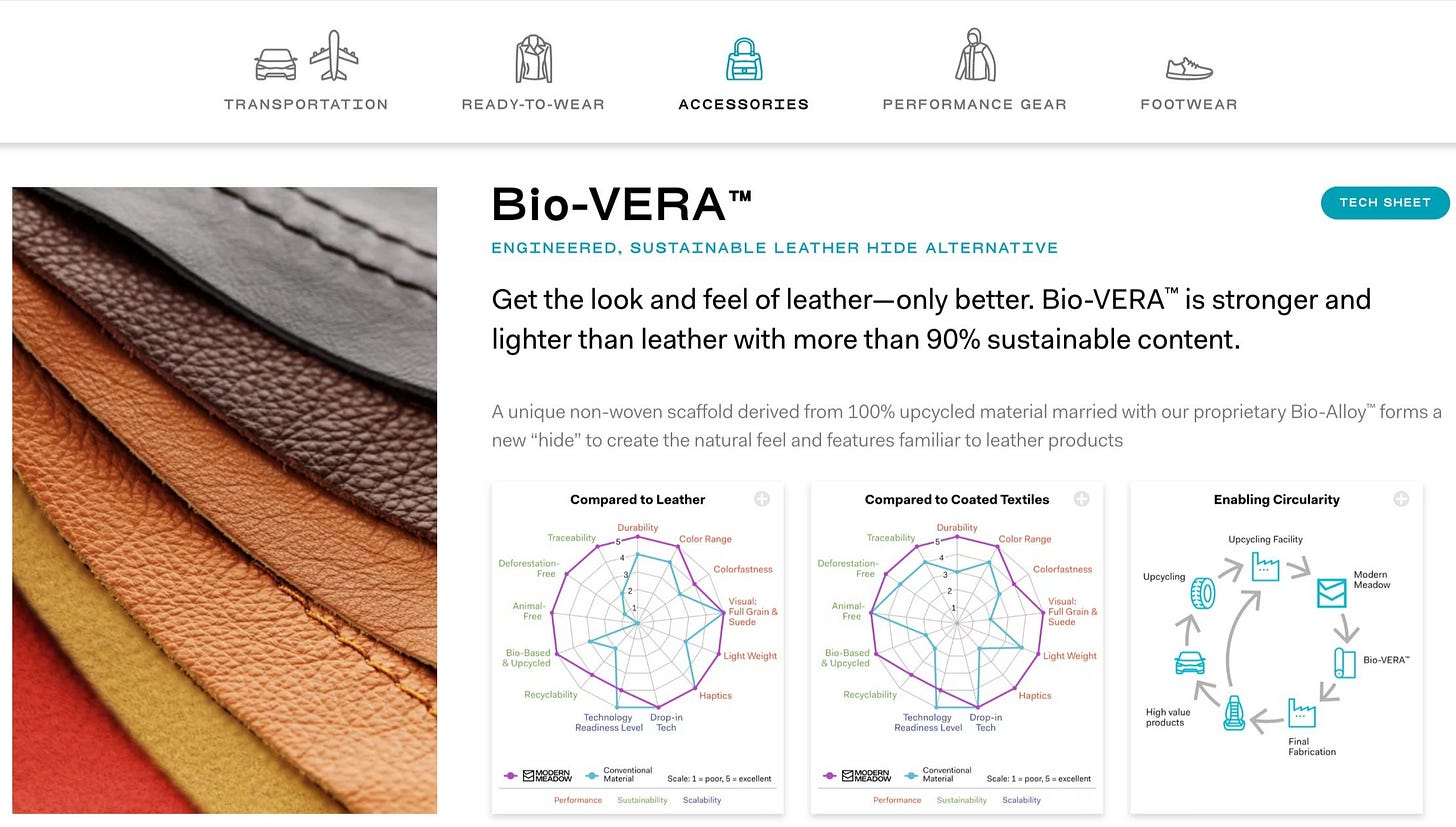

Modern Meadow spoke about their artificial leather in a panel on Leather, Luxury & Land. This technolgoy called Bio-VERA™ is stronger and lighter than leather with more than 90% sustainable content.

In the coming weeks, our team at Subject Matter will unpack several more conversations with leaders, startups and policy makers who are taking postive steps towards sustainability in fashion. Stay tuned!